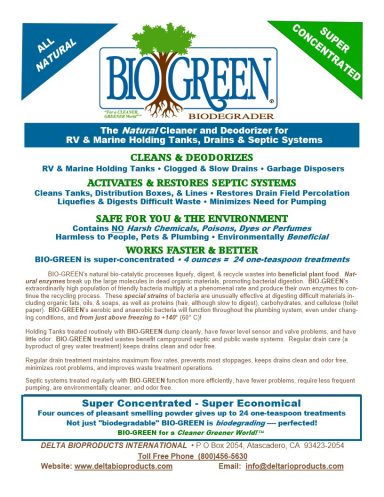

Learn more about DELTA BIOPRODUCTS below

DELTA BIOPRODUCTS

Directions/Maintenance/General Information/Troubleshooting

Learn more about BIOGREEN by clicking the images below.

MATERIAL SAFETY DATA SHEET

HANDLING, EXPOSURE, AND CHEMICAL PROPERTIES

STABILITY AND ECOLOGICAL INFORMATION

Troubleshooting

INTRODUCTION

There have been very few reports of odor problems by users of BIO-GREEN. Even with tens of thousands of users, Delta Bioproducts hasn’t confirmed a product failure. All reported failures have been traced to misuse, contamination, or other problems. Many of the things listed here are “theoretical” possibilities that may never have occurred.

CONTAMINATION

RESIDUAL CONTAMINATION: In Recreational Vehicles the

most common cause of failure to control odors is caused by residues of toxic chemicals. Of these, the most common is “caking” from the use of formaldehyde (formalin & other synonyms) and/ or paraformaldehyde (dry formaldehyde). Rarer, because it is used less, is contamination from glutaraldehyde (N-pentanedial), a dialdehyde more toxic than formaldehyde. There are several other toxic and biocidal chemicals sold for RV use which are potential sources of problems. Some of these chemicals react with organic wastes and cause a buildup of insoluble waste in RV holding tanks. Tank capacity is reduced (often dramatically) and the tank can be unusable. Other substances, usually not thought of as toxic, can also cause problems. These include chlorine compounds and bleaches, household disinfectants, borax, ammonia, acids and alkalis and other chemicals, sometimes used in “home brew” concoctions. Except for borax, most of these do not by themselves build up in the tank, but residual contamination

trapped in the waste cake can be a problem. When tanks are caked up with chemical impregnated waste, the result can be partial or total failure to control odor due to poisoning the friendly bacteria in BIO-GREEN. In such cases, flushing the tank per standard directions is usually sufficient. Though rare, users have had very good odor control using BIOGREEN and then have odor develop. Usually this is caused by a sudden dose of poison as the BIO-GREEN cleans out the tank, releasing large hunks of contaminated waste. In that event, dump, flush, and keep using

BIO-GREEN ... It’s working!

OTHER CONTAMINANTS

Most other potential contaminants are common household substances containing germicidal or other bio-incompatible chemicals. This

list isn’t exhaustive, however, it may help identify possible culprits.

Most waste systems can tolerate a certain amount of contamination, however, the RV system is small, so the dilution is less.

PRESERVATIVES: There are reports of septic systems deactivated by preservatives. Food preservatives passing through the human

digestive system or via other wastes were potent enough to disable a residential septic system! Presumably, RV holding tanks could also be affected.

DRUGS: Medications, especially antibiotics, taken directly as

medicine or indirectly through food, could have an effect on beneficial bacterial action.

OPERATIONAL DIFFICULTIES

SUPER-CHLORINATION: There have been no reports of difficulties due to super-chlorination of the RV’s fresh water supply. BIOGREEN is tolerant of normal amounts of chlorine, however, the possibility.

of over-chlorination exists.

VENT OBSTRUCTIONS: Obstructions in RV holding tank vents may be more common than reported data indicates. Plugged vents occur in residential systems when drain stoppages cause waste to back up into the vent. An analogous situation occurs in RV’s when tanks are overfilled or from sloshing during travel. Undigested solids forced into the vent can stick and dry in place. Plugged vents contribute to slow draining and cause the tank to become anaerobic. Under these conditions the tank pressurizes and odors can be forced into the rig (especially when flushing the toilet). BIO-GREEN minimizes the likelihood of vent plugging by digesting solids; however, it can occur before digestion takes place.

VENT CLEANING: Plugged vents can be cleared by hosing or cabling. Soft plugs will usually wash out. Hard (old) deposits may be removed by treating them with BIO-GREEN. Fill the tank with water until it goes up into the vent. Mix 1 to 3 teaspoons (5 to 15 ml.) of BIO-GREEN in a quart (1 liter) of lukewarm water. The water should be no hotter than comfortable to your hand. For best results, allow the mixture to activate for 45 minutes before application. During activation the mixture should be kept away from sunlight and other ultraviolet sources. In cold weather, filling the tank with warm water will give better results. Slowly pour the mixture down the vent and allow the treated tank to sit for as long a practical (a couple of days is desirable). Drain the tank and flush the vent from the top. Repeat if indicated in extreme cases.